Human hands are prone to error, especially when assigned to repetitive tasks. Robot grippers don't get tired even when assigned tasks 24/7.

Robot Grippers Explained

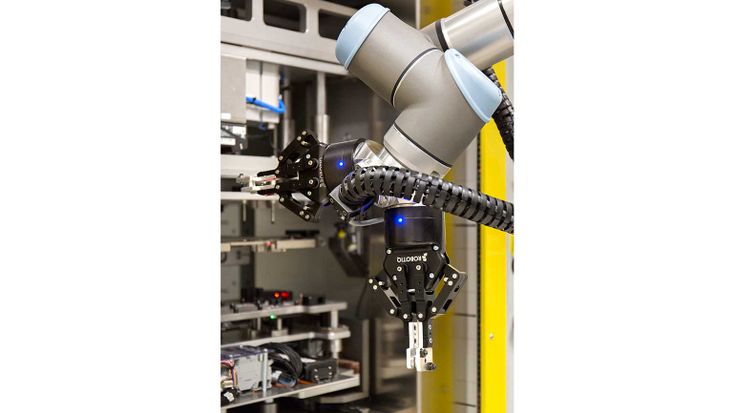

If you think of a simple industrial robot as consisting of an arm, with an 'elbow' and a 'wrist' for motion and a 'hand' for picking things up, you're not being childish –in fact, you're thinking like a roboticist. Industrial robot 'arms', as they are called, do have elbows and wrists. And, at the end of the arm, robots are often fitted with what are called grippers – special devices designed to help robots handle objects in the real world. Grippers are also known as 'end-effectors' or 'manipulators.'

Human hands are prone to error, especially when assigned to repetitive tasks. Robot grippers don't get tired even when assigned tasks 24/7.

Some grippers look just like hands, while others look like a hand with two or three fingers. Some grippers don't look like hands at all; they look more like robot claws. Other grippers come with giant suction cups. Some grippers look like a soft round ball. Some have magnetized tips. And grippers receive their power in different ways, from electrical to pneumatic (air) and hydraulic (hydraulic fluid).

The incredible variety of gripper types is due to the massive variety of objects robots can handle, from textiles to electronics components and automotive parts. For direct handling of delicate foodstuffs, for example, a small, soft gripper is likely to be the best choice. But for packaging and palletizing operations, where you need to stack boxes of product, a bulky gripper with large suction cups is probably the better choice.

Robots from Universal Robots are compatible with virtually every gripper type, including those listed above. In this article, we'll take a look at the some of the most common grippers.

When selecting a gripper, there are a few key considerations:

Application

Your choice of gripper should be guided primarily by the application you have in mind for your automation. Will it be handling small batch products? Does the gripper need to have strength or a delicate touch? Does the gripper have to be certified food safe?

The good news is that no matter which application you have in mind –handling delicate electrical components, for example, or assembly or palletizing large boxes-- you'll find the perfect gripper on UR+, Universal Robots’ ecosystem of 3<sup>rd</sup> party components certified to work seamlessly with UR robots.

Payload

Payload refers to the entire weight the robot arm is able to support, including the gripper. Just as your arm and hand can only lift certain weights at the gym, a robot can only handle so much weight without faltering. So, when choosing your robot hand, you must consider the payload capabilities of the robotic arm and the gripper itself.

Real world scenarios

Machine tending is a repetitive task that’s ideally suited to automation using collaborative robots. Instead of assigning workers to these manual tasks, consider using cobots fitted with grippers that can handle parts and take over machine operations. Not only will this produce more consistent results, but it will free your workers to work on higher value tasks better suited to human skillsets, such as, for example, overseeing your cobot’s programming and performance.

Imagine a quality inspection setup in a busy electronics manufacturing facility. A robot fitted with a gripper can be programmed to pick items from a conveyor at regular intervals and the gripper can then orient the part for inspection purposes before returning it to the conveyor.

One of the most common end-effectors for small-medium jobs are finger-style or jaw grippers. Finger grippers usually come in 2- and 3-finger styles. Robot grippers, especially those using fingers or jaws, often incorporate a “force sensor”, which controls the amount of force applied so as to avoid breaking or damaging the product at hand.

What are the types of robot grippers?

Collaborative robots from Universal Robots have been designed to be compatible with almost everygripper type:

Servo-electric grippers

These grippers feature an electric motor and a controller. The controller provides a signal relating to the force, position, or the speed required of the robot. The gripper receives the signal and its motor carries out the desired motion. Some servo-electric grippers have additional features that communicate with the control system. For example, when a part is picked up, the gripper sends this information to the control system. This is useful information that can be used to reduce errors on the production line.

Two-finger/jaw grippers

These grippers are commonly found in manufacturing environments for smaller jobs. The end-effector features two parallel jaws with flat edges. They open and close, clamping onto the part and keeping it stable with force. However, these types of grippers are not malleable when it comes to dealing with irregular shapes and sizes.

Three-finger/jaw grippers

Three-finger grippers feature three fingers or jaws that close onto the item and hold it in the center. These are commonly used for round or cylindrical items.

Adaptive or multi-finger

Adaptive grippers often have multiple fingers made from malleable, soft materials. They are designed for gripping round, irregular, and/or delicate objects. They may be used for food production lines, or for dealing with small, fragile items.

Magnetic grippers

As the name suggests, magnetic grippers use a magnetized surface to grab metal items. This type of gripper doesn't usually incorporate fingers or jaws, instead relying on smooth magnetic surfaces for handling. Magnetic grippers are common in industries where sheet metal and automotive parts are being moved along an assembly line.

Soft and flexible grippers

Soft, flexible robot grippers are made to handle delicate items without causing damage or scuff marks. For example, certified food safe soft grippers made of silicone are used for handling food or items that require a contaminant-free environment.

Jamming grippers

A fascinating robot gripper that uses granular materials – such as coffee beans or plastic beads – encased in a soft outer shell to grip and hold the item. A jamming robot gripper can adjust to different sizes and shapes, making it a versatile choice that's ideally suited for irregular item production. Jamming grippers work by gently touching the item, then air pressure is applied, causing the gripper's internal grains to “jam”, creating a secure grip. When the air is released, the granular material becomes “unjammed” again, dropping the item.

Hydraulic grippers

These are heavy-duty grippers that apply major force required for large or heavy items. Hydraulic grippers are designed with pistons, meaning they can be higher-maintenance than other gripper varieties.

Pneumatic grippers

Pneumatic grippers function using compressed air and pistons (unlike electric grippers). Pneumatic gripper systems require an air supply that exposes the gripper pistons to compressed air, triggering the gripper to close onto the item. The gripper opens and releases the item when the pressure is released.

Vacuum grippers

Vacuum grippers leverage the difference between internal gripper air pressure and external air pressure to lift, hold and move items. Suction cups act as the point of contact between the item and the robot gripper. Simply changing the size and shape and the suction cups will enable you to handle mixed product runs easily. Some vacuum grippers require an external air supply, but not all. Several vacuum grippers come with in-built vacuum generators powered by the same electrical supply as the robot, eliminating the need for an external air supply.

Whether you are seeking a gripper for delicate food handling or hardy steelwork, the market is abundant with solutions. Your Universal Robots robotic arm can be fitted with a wide range of grippers, ensuring consistent, error-free work.

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI