BWIndustrie, a French machine shop, has installed the new UR16e from Universal Robots to optimize and automate its deburring activities, which consist of removing burrs from machined parts. The company produces series ranging from 300 to 300,000 parts per year and wanted to guarantee the repeatability of the process. To solve these problems and optimize its deburring operations, BWIndustrie has deployed UR16e to handle the entire deburring operation. Its programming is carried out remotely by the operators via a TCP remote function.

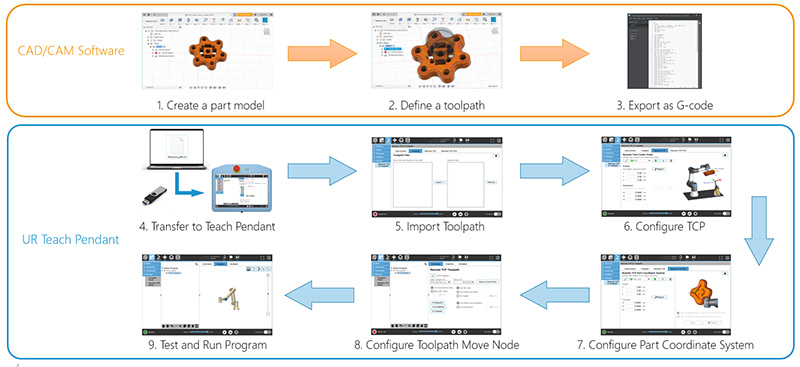

One way to address this challenge is robotic offline programming (OLP). First, you create a virtual work cell in the OLP software. Then, program and simulate the robot motion. Finally, the software outputs a program file that you can load onto your robot directly. For some customers, this may be an acceptable approach. But what if you don’t have the budget for OLP software or don’t have the right people to learn and use it? Are there any alternatives? We reviewed many solutions on the market and concluded there was a gap between basic waypoint programming and OLP. Therefore, we decided to release this new feature, G-code toolpath support, to fill the gap.

G-code is an industry-standard language used for CNC machining. It tells the motors in CNC machines where to move, how fast to move, and what path to follow. Robots are fundamentally similar to CNC machines as each joint is driven by a motor as well. We just need to find a way to interpret G-code and generate robot commands accordingly, which seemed quite feasible to our smart development team. We chose G-code in specific because it is widely supported by CAD/CAM software. There is no need for you to purchase or learn an additional piece of software if you are already using a CAD/CAM package. Other formats, such as DXF, are able to define the geometry of a path, but generally, they do not contain all the necessary information, such as tool orientation, speed, and acceleration, for robot programming.