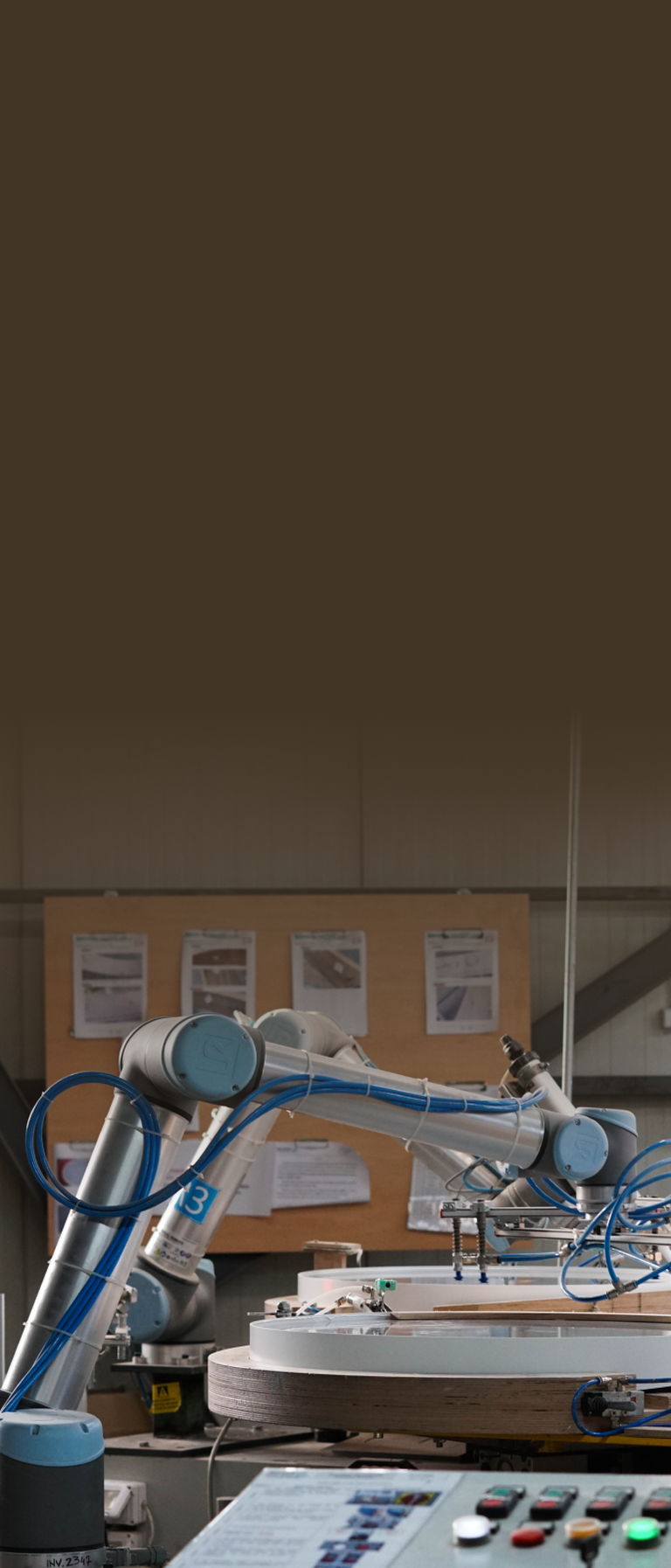

The two UR10 cobots integrated in the process of assembling mirrors work in tandem, as the first UR10 dispenses adhesive to the product frame, followed by the second UR10 placing another part, a ring segment, on top of the glue over the glass. Programming the cobots was easy and quick. From the UR interface, the company used the predefined program CircleMove with a relatively free orientation towards the circle.

The technical support provided by Universal Robots also played an important role in the successful integration of the cobots. "On the Universal Robot website you can find all the information you need, even backup files for the programs developed that are easy to save through the magic files on the website, and for the software updates. There is a whole community behind it, ready to help you with the answers you need,” Remus Țopan added.