Not having to spend resources on expensive and cumbersome safety guarding also helped make the collaborative robots attractive price-wise. “For the ROI on purchasing the cobots, I initially predicted it would take about sixteen months,” says Griffin, who was positively surprised as he saw the UR cobots pay for themselves in less than a year. “We’re running about 30 percent more efficient. I have more flexibility as it takes less staff to run that line, so I can focus people into different areas and run different products.” Instead of buildingonly two products a week, Darex can now build four products per week.

Cobots Take Over Undesirable Tasks, Optimize Assembly and Packaging by 30%

In Short

Darex, a manufacturer of drill and knife sharpeners, runs fast-paced production lines with many repetitive and ergonomically unfriendly tasks. The company has implemented Universal Robots in screw-driving and box-erecting applications, quickly scaling the initial install into a full-blown automation line with multiple work stations programmed through the Universal Robots interface. The entire system is developed in-house.

The challenge

Darex, a fourth-generation, family-owned company based in Ashland, Oregon, needed to add more products to its lines without hiring more people. “Basically, I need to do more with the same amount of resources,” says John Griffin, director of operations at Darex, explaining that the Ashland area is experiencing a shortage of available workers. Darex also needed asolution that wouldn’t need a new dedicated space. “We have a small production area, so I wanted something that wouldn’t require a separate cell but would fit right into our assembly line,” says Griffin, who was looking to automate the company’s screw driving application assembling the plastic housing of the knife sharpener along with the station where boxes are erected and packed with product cartons. For erecting boxes, the company considered using box constructors. “But they were limited in what they would do and only work on a certain range of boxes. We wanted more flexibility,” says Griffin.

Darex

The solution

Griffin had seen Universal Robots at many trade shows. “They appeared to be simple to program, and even vendors who weren’t selling robotics were using these robots in their booths,” he recalls. “So that kind of told me, ‘Wow, this really is the most popular one.’” One of the reasons for the cobots’ widespread use is their built-in safety mechanisms that automatically stop the cobot arm when it encounters obstacles in its route. Once a risk assessment is performed, the cobots can then operate without safety caging. “Now I can have people work right next to the cobots without a bunch of caging,” says the operations director.

John Griffin, Director of operations, DarexWe’re running about 30 percent more efficient. I have more flexibility as it takes less staff to run that line, so I can focus people into different areas and run different products. Before, we would only build two products per week, now we can build four products per week.

ROI in less than a year, 30% efficiency increase

Screw driving: the low-hanging fruit ripe for automation

The task of assembling the knife sharpeners seemed like a logical place for Darex to start their automation project. “Traditionally we would have an operator with a pneumatic screw gun retrieving a screw from a screw presenter, sticking it into the machine, and driving it to torque—very monotonous, very ergonomically unfriendly work,” says Griffin. To alleviate the operators from this undesirable task, Darex chose the UR3 tabletop cobot. The company was able to keep the exact same setup with the screw presenter and the screw gun; the only thing that differed was the cobot now doing the task. Sam Jacobson, production engineering supervisor at Darex, recounts how operators would sometimes miss screw insertions as the holes in the housings were hard to see into. “The UR3 hits all the screws all the time and if not, it will immediately notify us,” he says. “We have definitely seen an increase in product quality due to the cobots.”

The cobot becomes the brain

The success of the screw-driving application quickly spurred Darex to look at its whole assembly line setup in a new light. “Since our first application went so smoothly, we decided to up the ante and add the conveyor system and all the PLCs controlling things like the pneumatic press and add another UR robot on the boxing side of it,” says Jacobson. “I actually decided to use the UR controller to program and handle the entire line, using Modbus communication to connect the different PLCs through the UR cobot’s teach pendant,” he explains. “I could program that entire thing so quickly, I was really happy with that decision.”

Box erecting: UR5 handles multi-step cycle

Folding boxes into shape and packing them with products was another unpopular, ergonomically unfriendly task at Darex. Universal Robots’ mid-sized cobot, the UR5, took over and is now handling the entire cycle that starts by the cobot grabbing a box out of a cassette and folding it into shape. It places the folded box on a staging platform, grabs four individual cartons arriving on the conveyor, and loads them in the box. When the box is full, the cobot closes the lid and pushes the box through the taping station.

The contest to become darex’s new robot technician

When Darex initially bought the cobots, the production supervisor was trying to think of ways to get the production team excited about having a robot amongst them. He also needed a dedicated staff member on the line to be the robot technician who could oversee all robot operations. “So I came up with this little competition,” says Griffin. “I gave everybody the UR Academy web address, told them to study up on this and invited them to compete for the job, using the knowledge from the Academy.” The UR Academyconsists of nine interactive, online modules that cover the basic UR cobot programming and setup. Darex held several rounds of contests where employees were required to program the cobots. The winner was 26-year-old Brittany Mohrman. “It was really exciting to get the opportunity to do something different, so I jumped right in, learned all I could, aiming to beat out the competition. The UR training taught me things like understanding different program cycles, adjusting waypoint changes, and knowing where the tool center point of gravity on the robot is. My job is definitely more interesting now.”

Palletizing is next

The next task Darex is looking to automate is palletizing boxes as they exit the tape-sealing station. “Many of our products and boxes are very similar in size and shape, so it seems like that would be a good next application,” says Griffin. “It would also keep our employees from having to reach and bend over all the time. Looking at the assembly line we’ve already created, we could also easily take that and replicate it two or three more times in our production area and accomplish the same thing with other products.”

Efficient Packaging Automation

Universal Robots’ UR5 cobot handles the entire box erecting and packaging cycle at Darex; the cobot grabs the cardboard out of the cassette, folds it into shape, adds four cartons, closes the lid and pushes it through the tape sealer and down the outbound conveyor.

Safeguarding Productivity

The UR cobots have a built-in, force-limiting safety system that makes the cobot arm automatically stop if it encounters unexpected obstacles in its route. As an added safety precaution, Darex has added area scanners that are activated when employees cross the yellow and black striped lines on the floor (visible on the right) outlining the boundaries of the work envelope. Once the area scanners are activated, they send a signal to the robot to slow down its operating speed. When the employees leave the work envelope, the cobot picks up its usual speed.

Young Talent Shines

26-year-old Brittany Mohrman is Darex's’ new ‘robot technician.’ Using the free online robotic training modules through the UR Academy, she won the company’s programming contest for the job.

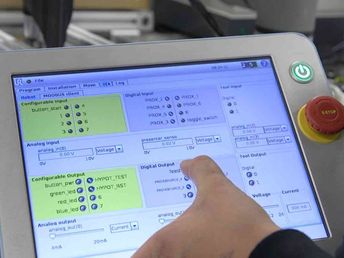

Seamless Control and Monitoring

An overview of the Modbus-controlled stations along with all the inputs and outputs and their status in real-time is available right through the UR cobot’s own teach pendant where the operator can now control the entire assembly line.

Automation challenges solved:

Achieved 30% efficiency increase Production flexibility enabling four product builds per week vs. two in the past Product quality increase in screw driving application Ability to automate without safety caging, enabling side-by-side operation with line workers Zero maintenance with no down-time or interruptions of the line Elimination of repetitive and ergonomically unfriendly workflows

Key value drivers:

Less than 12 months ROI Easy programming Collaborative and safe Ability to control entire assembly line through UR controller

Tasks solved by collaborative robots:

Box erecting, packaging Screw driving Assembly line control

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI