Olympus is a leading manufacturer of test and measurement solutions used in aerospace, oil and gas, automotive, and other industrial applications. Olympus' inspection systems can be used to detect and characterise defects, and non-destructively measure elemental compositions in a range of materials such as metals, plastics and composites.

Automating processes with UR cobots optimizes workflow

In short

Non-destructive testing (NDT) are inspection methods used to identify cracks or defects in materials, or determine the elemental composition of materials without damaging it. Olympus has a wide range of NDT devices which are versatile and have a variety of measurement features that allow end-users to conduct inspections, detect defects, measure thickness or elemental compositions in a range of materials such as metals, plastics, ceramics, and composites used in diverse industries.

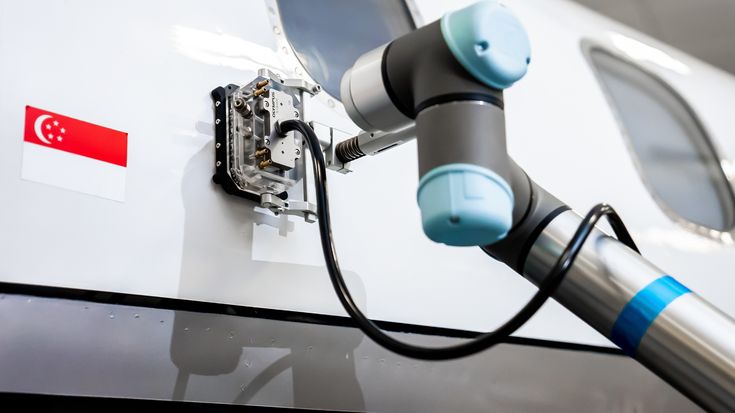

For example, the Olympus NDT equipment is widely used for aircraft inspection in Singapore, a regional aviation hub. Aircrafts are exposed to strong torque and forces, as well as in environments with extremes in humidity and temperature, all of which can affect surfaces and molecular structures that can directly impact performance and flight safety. Periodic inspection, using the non-destructive testing (NDT) method, is an essential part of ongoing maintenance program for aircrafts to ensure the integrity of the aircraft for crew and passenger safety.

Another major usage of NDT is the verification of precious metals. NDT provides immediate on-site elemental measurements for precious metals include gold bars, platinum, and silver using the X-ray fluorescence (XRF) method, and ensuring that such metals are free from any inclusions with the ultrasonic method.

The business transformation

Today, NDT inspections provide high precision testing repeatedly as desired. In an aviation setting, operators may have to move components or probes across the entire aircraft to locate and size hidden cracks, corrosions, voids, disbonds, delaminations, discontinuities in welds, around the turbines and other structural components as part of the maintenance process. It is common to see dozens of human operators inspecting an aircraft using Olympus NDT devices at one time, especially for larger aircraft.

In the case of verification of precious metals, operators often have to perform such monotonous processes repeatedly. As they may be working in uncomfortable or even unsafe positions over extended periods of time, it escalates potential health and safety risks due to fatigue and repetitive strain.

Olympus

A leading manufacturer

Empowering worker satisfaction

Inspection tasks are often carried out over an extended period of time, in uncomfortable or even unsafe positions, presenting scenarios that may lead to incidents or accidents caused by fatigue, repetitive stress, and bad human factors. By incorporating collaborative robots from Universal Robots (UR), Olympus provides a complete and efficient automation solution to their clients. These solutions relieve operators from potential health and safety hazards due to long hours of repetitive work in uncomfortable positions, and enable them to focus on activities such as optimising inspection methods, analysing data, and other value-added tasks.

Dr. Christopher Lane, Manager, Olympus APAC Technology CentreTogether with UR, we hope to add more adaptiveness to the UR cobots and our NDT products

Removing repetitive tasks

Olympus collaborated with UR to implement cobots to free the operators from repetitive and monotonous task so that they can focus on activities such as optimising inspection methods, analysing data and other value-added tasks. The integrated solution comprising UR cobots and Olympus' NDT equipment, enable clients to deploy a complete and efficient solution while relieving operators from potential health hazards due to long hours in constrained positions.

An ecosystem of support

One critical requirement for many customers is having to maintain these cobots over time. Both Olympus and UR have a global network and dedicated local presence which avails customers with short lead time for replacement parts and readily available service engineers for support. UR+, another unique UR offering, provides access to the largest ecosystem of third-party plug-and-play cobot accessories and applications kits, designed for repeatable success and assures clients of a future-proof solution.

Looking to the future

Moving forward, Olympus aims to collaborate more with research institutes in Singapore to lower the barrier to automation by ensuring end users have the capability to operate cobots with NDT devices more efficiently. Olympus aims to become a workflow solution provider under the new company name Evident. Olympus supplies Olympus products integrated with UR cobots for comprehensive automation solutions to their clients for higher efficiency and operator safety.

"Our goal is to empower students to embrace the robotic age, providing them intensely rewarding internship and training opportunities for a profitable and productive future. We support institutes such as Nanyang Polytechnic (NYP) by providing training to students while NYP collaborates with us to test our solutions at their extensive facilities" says Christopher Lane.

Automation challenges solved:

Free operators from repetitive and monotonous task Relieves operators from potential health hazards due to long hours in constrained positions

Key value drivers:

Global network and dedicated local presence which avails customers with short lead time for replacement parts and readily available service engineers for support Access to the largest ecosystem of third-party plug-and-play cobot accessories and applications kits, designed for repeatable success and assures clients of a future-proof solution

Tasks solved by collaborative robots

Aircraft inspection to maintain integrity of aircraft for crew and passenger safety using the non-destructive testing (ndt) method Verifying that precious metals are free from any inclusions using the x-ray fluorescence (xrf) method

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI