A truly universal bin picking solution needs to be usable by non-experts, configurable in a few hours, provide sophisticated path planning that works with little or no tuning and be cost-effective for SMEs.

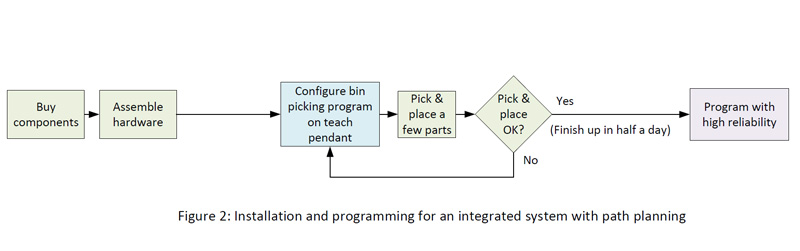

Energid is democratizing automated bin picking by providing a complete pre-integrated system, with all the complexity managed by the underlying software. All the system components (sensor, imaging, and path planning software and co-processor) are pre-configured and plug into the robot controller with no setup required. This reduces installation time to mere hours.

All programming is integrated with the UR cobot’s teach pendant through the UR+ platform, enabling bin picking actions to be freely mixed with standard robot commands using the same programming interface. Training time is minimal. Setup and programming are guided by a series of wizards that mimic the training a human operator would have to go through, e.g. how to pick up a part, where to put it down, obstacles to avoid, etc.

Automated path planning is key to ease of use and reliability

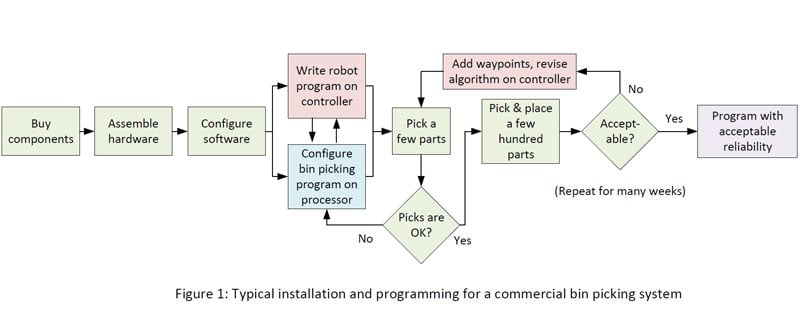

Planning a unique collision-free path for each part in the bin to the placement target is by far the trickiest challenge for bin picking, and is often left to the ingenuity of an automation expert. Path planning is the main determinant of system reliability, and if not done well will result in collisions, parts left in the bin or dropped, and missed targets.

Energid’s bin picking solution leverages Actin, the intelligent path planning and motion control software that has been proven in mission-critical applications like NASA spacecraft, autonomous robots on oil drilling platforms, surgical applications, and industrial automation. Behind the scenes and in real-time, Actin automates the path planning for each part, improving performance and reliability, without the need for user-defined waypoints and manual tuning.

Finally, a bin picking solution for SMEs

So, can we declare that the bin picking problem has been solved once and for all, and manual machine tending is a thing of the past? Not quite, since there will always be applications that are just too complex for automation, and will require human operators for the foreseeable future. However, advances in cost-effective cobots, 3D imaging, and intelligent motion control software have aligned to enable a new generation of bin picking solutions that can handle many more of today’s machine tending applications, and enable manufacturers to shift their limited resources to higher-value tasks. More importantly, bin picking is now accessible and cost-effective for SMEs. Finally, a bin picking solution for the rest of us.