In this fast-moving sector, agility is the key to competitiveness. Whether you’re building sub-assemblies, loading and unloading test fixtures, or kitting and packaging products, flexible collaborative robots can improve productivity, quality, and consistency.

Electronics & Technology

Collaborative robots in Electronics & Technology

Safe alongside workers (after a risk assessment), cobots can handle precise tasks such as insertion, gluing, screwdriving, or labeling with high repeatability. As you automate these repetitive processes, you can reassign skilled workers to more valuable tasks. Collaborative robots are also an ideal way to distance workers on production lines, by filling in upstream or downstream processes.

Cobot arms are lightweight and easy to program, so they can be easily moved from one production line to another—or moved from production to packaging or palletizing—as needed. Even in competitive electronics manufacturing, cobots can pay for themselves in under a year.

Case stories

Cobot automation in electronics manufacturing

Cobots are transforming the electronics manufacturing industry by handling tasks such as screwdriving, assembly, and testing. These flexible robots help manufacturers like Siemens increase productivity in small to medium volume production. With intuitive programming and digital twin planning, cobots ensure smooth integration and reliable performance, allowing for in-house application development and reducing labor shortages.

Cobot solutions for electrical component production

In the production of electrical components, cobots play a crucial role in automating repetitive tasks such as assembly, testing, machine tending and packaging, . Companies like Schneider Electric utilize cobots to handle different component sizes with precision and flexibility, improving ergonomics for operators and significantly shortening production cycle times.

Boosting efficiency in PCB packaging

Cobots are revolutionizing the packaging of printed circuit boards (PCBs) in the electronics and technology sector. With the ability to handle multiple workpieces simultaneously, cobots enable companies like Melecs to increase productivity by 25% while operating in three-shift systems. These cobots automate repetitive tasks such as pick and place and packaging, relieving employees from monotonous work and ensuring faster, more cost-effective production.

Enhancing flexibility in circuit breaker production

In the production of modular DIN rail switches and other circuit breakers, cobots automate critical tasks like quality control and material handling. Cobots are equipped with suction cups that adapt to varying component sizes, making them an ideal solution for companies like Schneider Electric, where they improve production efficiency, reduce manual labor, and deliver a return on investment in around two years.

Automating material handling in electronics production

Material handling tasks in electronics production, such as moving parts between production lines and packaging stations, are being automated with cobots. These robots not only reduce physical strain on workers but also optimize the entire production process. Cobots offer flexibility and precision, making them ideal for tasks requiring careful handling and repetitive actions.

Talk to a cobot expert who knows your industry

Our automation experts work with companies like yours to identify applications where cobots can have the biggest impact. They can guide you on training and integration and calculating return on investment.

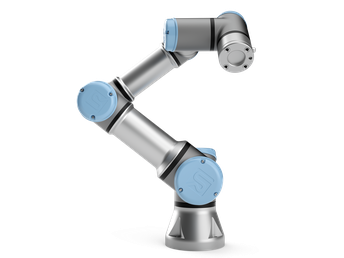

Collaborative robots for Electronics & Technology automation

A range of Universal Robots models are available to address automation needs from precision tasks to long reach and high payload requirements.

Why Universal Robots?

Tried. Tested. Trusted.

Universal Robots has deployed over 100,000 cobots into every manufacturing industry. Companies of all sizes, from Fortune 500 giants to local contract machine shops, are leveraging our 6th generation cobots to increase productivity and quality and improve job satisfaction for their manufacturing teams.

Flexible

UR cobots meet the demands for flexibility head-on with industry-leading ease-of-use, intuitive programming, and a powerful back-end for OEMs and developers to add value and meet specific needs. UR cobot-based systems generate ROI that is usually measured in months, not years.

Worker-safe, worker-friendly

Universal Robots has developed the most complete set of safety tools and functions in the industry. Our safety protocols can be configured to meet the varied safety requirements of your plant or facilities and your application risk assessment, letting your manufacturing team work safely side-by-side with UR cobots.

Get your Electronics & Technology e-book

Want to know more about collaborative robots in the electronics and technology sector?

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI