With easy deployment, robot set-up for medical and cosmetic applications is typically measured in hours or days, not weeks. Lightweight collaborative robotic arms can be easily moved from one process to another on mobile carts, and a single robot can often tend multiple machines.

Medical & Cosmetics

Collaborative robots in Medical & Cosmetics

As medical and cosmetic product lifecycles shrink, collaborative automation provides manufacturing agility. Robot arms from Universal Robots can be used to maximize output and ensure consistent quality. Cobots are used throughout the industry to tend machines and conveyors, precisely assemble devices and products and kit and package items into blister packs, cartons, or pallets.

Cobots help you reduce the risk of human contamination in sensitive processes and clean environments. Robots can also relieve workers from material handling jobs in dusty, loud, and high-vibration operations, allowing them to move to higher-value tasks. And with UR+ approved vision systems, cobots can perform detailed quality inspections.

Case stories

Robot automation in cosmetics manufacturing

Cobots are revolutionizing the cosmetics and consumer goods industries by automating repetitive and labor-intensive tasks such as picking, placing, and packaging. Whether handling makeup, skincare products, or other packaged goods, cobots ensure precision, flexibility, and cost savings. Mobile cobot deployment allows for quick changes between product lines, increasing production efficiency and quality control while reducing manual labor costs.

End-of-line packaging and palletizing in Pharmaceutical & Cosmetics

In the pharmaceutical and cosmetics industries, cobots are automating key end-of-line processes, such as palletizing and blister packaging. Cobots streamline the packaging of medicines, cosmetics, and personal care products, reducing manual labor and improving production efficiency. Whether handling boxes or delicate blister packs, cobots offer flexible deployment across different product lines, minimizing downtime and ensuring safe, ergonomic work environments for employees.

Precision manufacturing in medical devices

In medical device manufacturing, precision handling of tiny components is crucial. Cobots are used for tasks such as pick and place and injection moulding, ensuring accuracy in the production of intricate parts. The six-axes flexibility of the robot allows it to handle complex movements and small components with ease, improving production consistency while reducing downtime. Cobots are especially valuable in automating high-mix, low-volume production runs common in the medical device industry.

Flexible automation in precision manufacturing

For industries that handle sensitive materials, such as pharmaceuticals or scientific equipment manufacturing, cobots provide a reliable solution for repetitive tasks. Cobots are used in precision processes such as machine tending and forming, handling delicate materials with care. Automation in these areas helps stabilize production, improve quality, and increase efficiency across both small and large production runs.

Lab automation for sample analysis in pharmaceuticals and diagnostics

In pharmaceutical and diagnostics laboratories, cobots are improving the speed and accuracy of sample analysis. Cobots automate tasks such as sorting and preparing samples for analysis, handling increased volumes without additional staffing. These robots work safely alongside lab technicians, reducing the risk of contamination and ensuring faster response times, making them ideal for applications in blood, chemical, or biological sample handling.

Learn about collaborative automation within pharma & life sciences

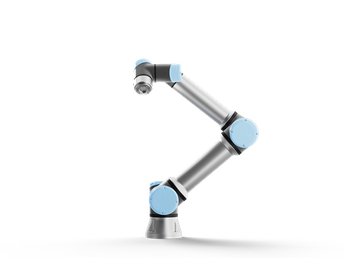

Choose the right collaborative robot for your applications

A range of Universal Robots models are available to address automation needs from precision tasks to long reach and high payload requirements.

Why Universal Robots?

Tried. Tested. Trusted.

Universal Robots has deployed over 100,000 cobots into every manufacturing industry. Companies of all sizes, from Fortune 500 giants to local contract machine shops, are leveraging our 6th generation cobots to increase productivity and quality and improve job satisfaction for their manufacturing teams.

Flexible

UR cobots meet the demands for flexibility head-on with industry-leading ease-of-use, intuitive programming, and a powerful back-end for OEMs and developers to add value and meet specific needs. UR cobot-based systems generate ROI that is usually measured in months, not years.

Worker-safe, worker-friendly

Universal Robots has developed the most complete set of safety tools and functions in the industry. Our 17 safety protocols can be configured to meet the varied safety requirements of your plant or facilities and your application risk assessment, letting your manufacturing team work safely side-by-side with UR cobots.

Get in touch

Thousands of businesses rely on UR collaborative robots to...

· Increase productivity

· Adapt to changing product demand

· Improve employee well-being and retention

· Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI