The new normal in manufacturing requires truly flexible automation to meet shorter product life cycles and changing customer demands. Collaborative robots meet these demands for flexibility head-on.

Metal & Machining

Versatile automation for diverse applications

In today’s manufacturing landscape, unfilled positions and idle equipment can quickly erode revenue and profits. Skilled workers like welders, machine loaders, assemblers, and material handlers are increasingly challenging to hire and retain, undermining productivity. Collaborative robots offer a dependable solution, keeping machine utilization and productivity high by working alongside your team, around the clock. UR cobots seamlessly handles tasks like machine tending, welding, palletizing, screwdriving, sanding, deburring, surface finishing and more, freeing your skilled staff for higher-value and more rewarding roles – a true win-win.

Case stories

Boosting uptime and flexibility in machine tending

Cobots are transforming machine tending by automating repetitive loading and unloading tasks across CNC machines, milling, lathes, and press brakes. Their compact size and flexible deployment ensure continuous operation, even in lights-out environments. This improves uptime, optimizes machine utilization, and allows skilled workers to focus on more valuable tasks, boosting productivity without the need for additional staffing.

Efficient welding automation across multiple techniques

Cobots are addressing the global shortage of skilled welders by automating welding tasks across various techniques, including MIG/MAG, TIG, spot welding, brazing, and plasma or oxy-fuel cutting. Compact cobot welders easily fit into standard welding cells and increase production capacity without the high costs of traditional automation. With the ability to program precise and consistent welds, cobots are enhancing weld quality and productivity.

Automating packaging and palletizing for enhanced efficiency

Cobots offer a reliable and flexible solution for automating end-of-line packaging and palletizing tasks. These robots can handle a wide variety of packaging formats, stacking patterns, and load types, reducing worker fatigue and increasing throughput. Cobots are perfect for industries facing labor shortages or high-demand periods, ensuring that businesses can meet production goals efficiently.

Versatile automation for complex assembly tasks

Cobots excel at automating complex assembly tasks such as screwdriving, riveting, snap-fitting, and pick-and-place. By relieving workers from repetitive and ergonomically challenging tasks, cobots help increase efficiency, reduce errors, and maintain high-quality assembly processes. Their flexibility allows for quick redeployment to different tasks, ensuring a versatile production floor.

Efficient material removal with robots

Collaborative robots provide an ideal solution for automating material removal tasks, including grinding, deburring, milling, and drilling. By taking over repetitive and potentially hazardous tasks, cobots improve worker safety while ensuring consistent, high-quality results. These robots are easily programmable for various removal processes, making them a flexible choice for industries looking to improve throughput and reduce injuries.

Ready to get started?

Speak to a cobot expert today to see how you can find your tailored solution.

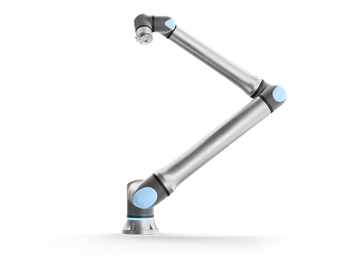

Choose the right collaborative robot for your applications

A range of Universal Robots models are available to address automation needs from precision tasks to long reach and high payload requirements.

Why Universal Robots?

Tried. Tested. Trusted.

Universal Robots has deployed over 100,000 cobots into every manufacturing industry. Companies of all sizes, from Fortune 500 giants to local contract machine shops, are leveraging our 6th generation cobots to increase productivity and quality and improve job satisfaction for their manufacturing teams.

Flexible

UR cobots meet the demands for flexibility head-on with industry-leading ease-of-use, intuitive programming, and a powerful back-end for OEMs and developers to add value and meet specific needs. UR cobot-based systems generate ROI that is usually measured in months, not years.

Worker-safe, worker-friendly

Universal Robots has developed the most complete set of safety tools and functions in the industry. Our 17 safety protocols can be configured to meet the varied safety requirements of your plant or facilities and your application risk assessment, letting your manufacturing team work safely side-by-side with UR cobots.

Get your Metal & Machining brochure

Want to know more about collaborative robots in the metal and machining sector? Get the latest Metal&Machining brochure.

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI